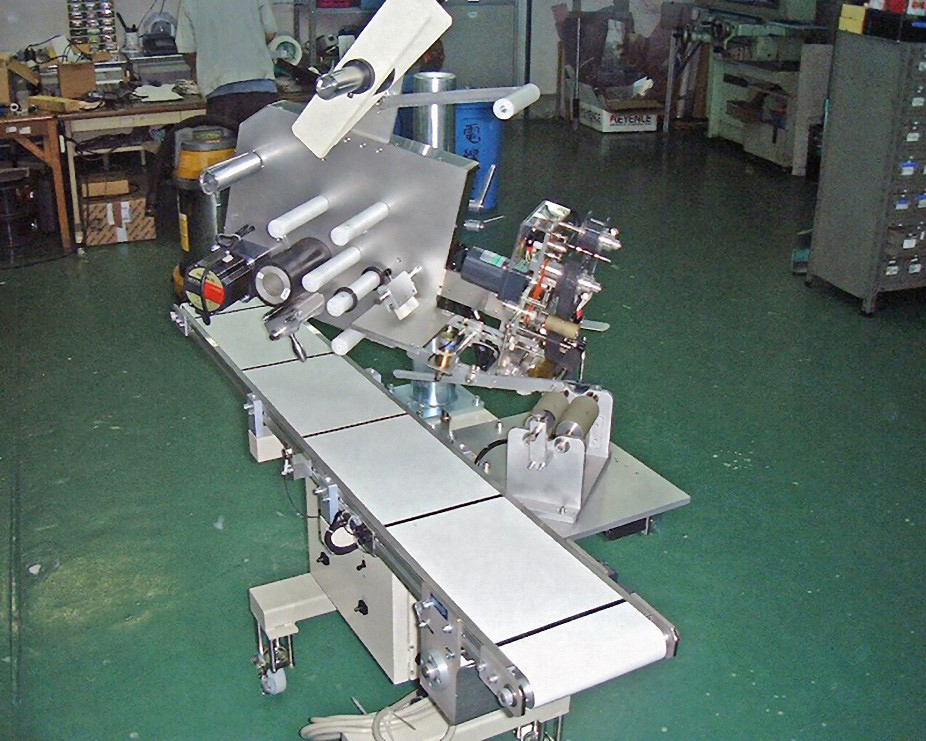

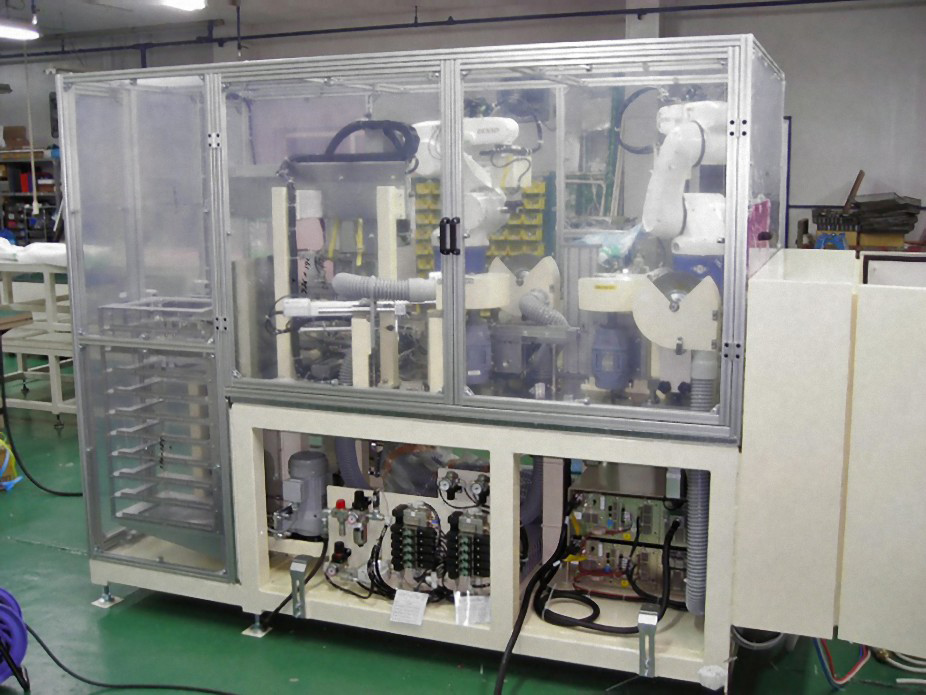

SKILL Automatic bag feeding with automatic bag filling sealing machine "Osamaru" SK-B-R1 (Wide variety of available type)

Insert fully automatic items for display with header bag, and then seal the entrance as well.

We design and manufacture by hope and products shape the insertion portion and work conveyor.

- Specification

-

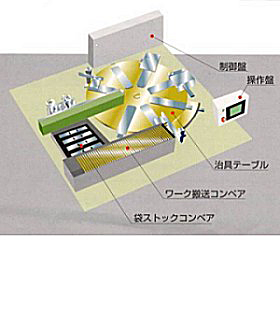

| System configuration |

| Packaging machine |

Index - Table |

| (Transport unit) |

(8 split roller gear system) |

| Electrical control |

Sequencer built-in liquid crystal display (touch panel) |

| Products providing unit |

Flat on the conveyor. (Disconnect automatic insertion) |

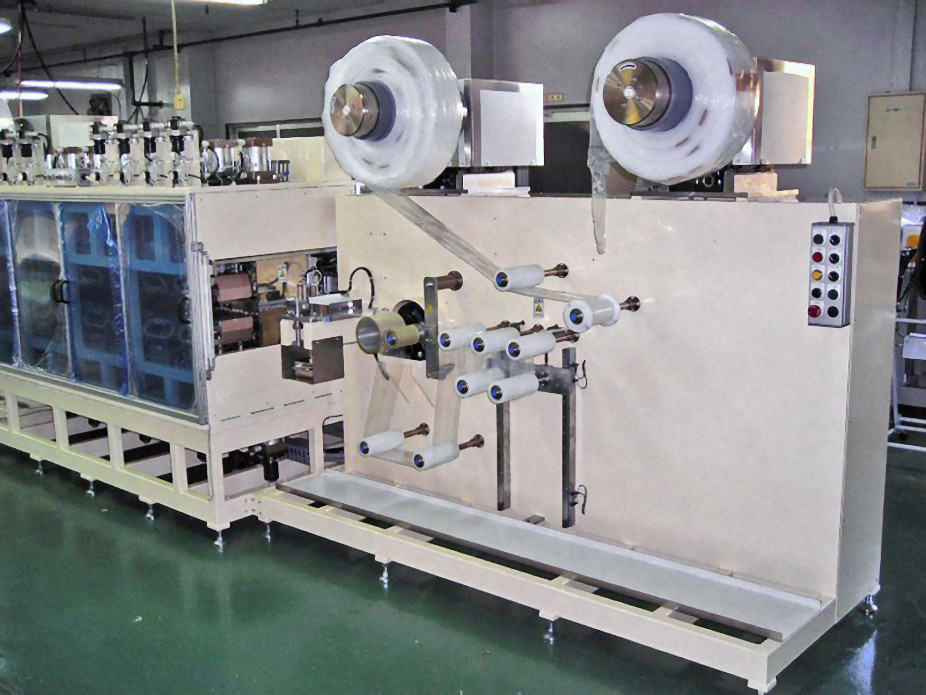

| Bag supply unit |

Stock conveyor standard equipment. (The supply in the short-axis robot) |

| Ejecting section |

The discharge at P & P to the flat conveyor on |

| Printer unit |

Rod printing, POS code, number etc. printing ( option ) |

| (Labeler section) |

Adhesive labels etc., equipment paste( option ) |

| Power source |

| Power |

AC200V 3 phase (1.2KVA) |

| Air source |

4.0Kg/m² |

- Processing power

- 30/m(By work insert)

- Packaging Products

-

Pen stationery supplies

Gauze, bandages, Medical Supplies

Lipstick, mascara cosmetics

Fishing tackle, appliances supplies

Razor, toothbrush, cleaner, cloth such as daily necessities

Socks, gloves, etc. clothing, miscellaneous supplies, etc.

- Specifications bag size

-

Available MAX(Standard machine)

W:65 * H:300 ~

W:150 * H:150 ~

< Resize converted by the jig tray or pin >

- Location mechanism stocks loading bag

- Standard machine type, about 1,000. (200 sheets * 5 ream)

- Exclusions

-

- Production, and work bag to use when commissioning (Your payment)

- Construction and optional equipment that are not listed

- Carrying expenses

- Option

-

- POS labeling equipment

- Printer

- Automatic product feed hopper

- Fusing sealing machine equipment (sealed type)

- Failure discharge device (camera image recognition system)

- Product counting emission control

- Boxed and alignment equipment

- Bag size change jig